Fiber optic technology revolutionizes the way we transmit data over long distances. Unlike traditional copper wires, fiber optics use thin strands of glass or plastic fibers to carry light signals.

These light signals can transport large amounts of data at incredibly high speeds, making fiber optics the backbone of modern telecommunications, internet, and cable systems.

The advantages of fiber optics include higher bandwidth, lower signal loss, and immunity to electromagnetic interference, ensuring cleaner and more reliable data transmission.

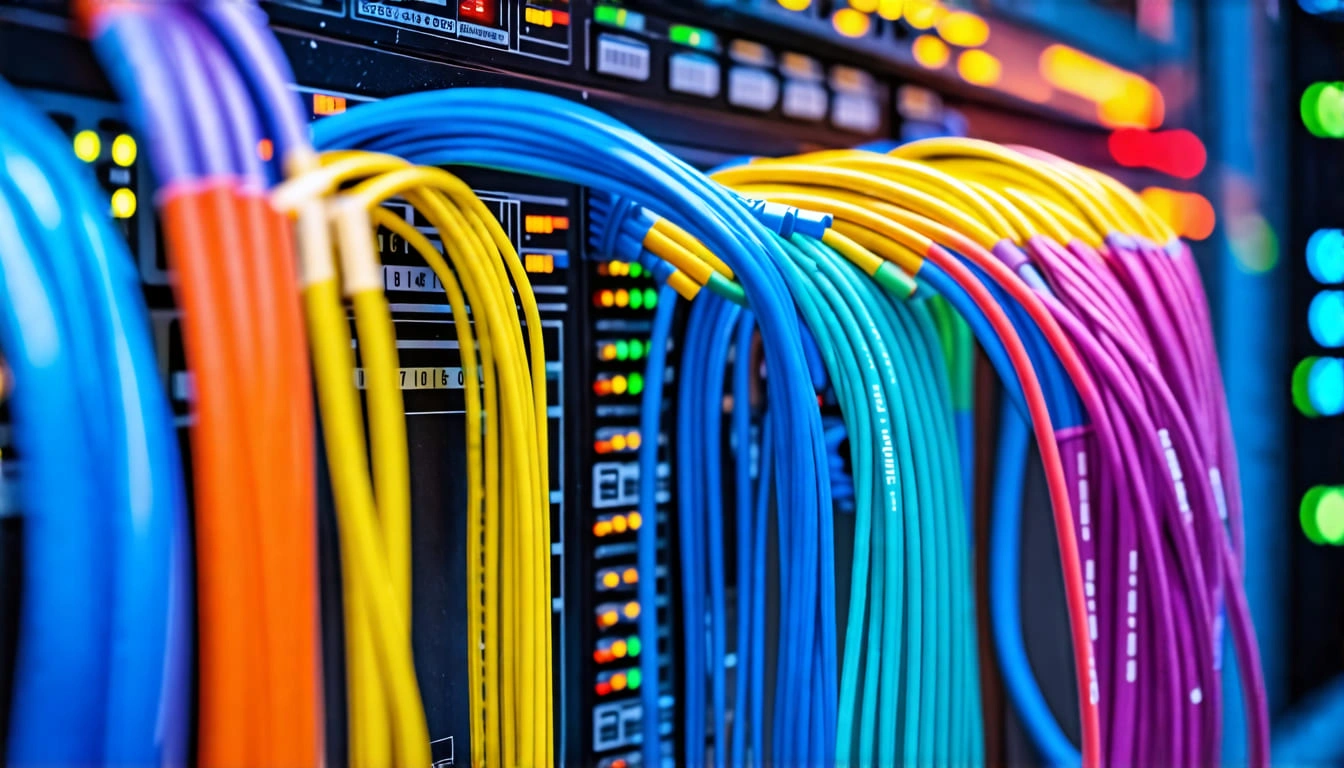

In the complex world of fiber optic networks, proper organization and identification are crucial. The fiber color code system is a standardized method that helps technicians quickly and accurately identify individual fibers within a bundle.

Each fiber is assigned a specific color, making it easier to trace connections, perform maintenance, and troubleshoot problems. Without a standardized color code, the risk of errors rises, potentially leading to downtime, increased maintenance costs, and degraded network performance.

Therefore, understanding and adhering to fiber optic color codes is essential for ensuring operational efficiency and reliability in fiber optic systems.

The goal of this guide is to equip you with the knowledge and skills to effectively understand and apply fiber color codes in your work. Whether you are a seasoned technician or new to the field, this guide aims to provide clear, practical information that will help you navigate the complexities of fiber optic networks.

By mastering the color code system, you can improve your workflow, reduce the likelihood of errors, and contribute to the optimal functioning of fiber optic infrastructures.

What is Fiber Color Code?

Fiber color code is a standardized system used to identify individual fibers and fiber bundles within a fiber-optic cable.

By using a predetermined color scheme, technicians and engineers can quickly and accurately distinguish between different fibers, ensuring efficient installation, maintenance, and troubleshooting.

Definition and Purpose

The primary purpose of fiber color coding is to facilitate the identification of fibers within complex fiber-optic networks.

Each fiber within a cable is assigned a specific color, making it easy to follow and organize during splicing and connecting operations. This systematic approach reduces the risk of errors and improves overall network reliability.

History of Fiber Color Coding

The practice of color coding in fiber optics dates back to the early days of fiber-optic technology. As fiber networks began to expand, there was an increasing need for a standardized method to manage the growing number of fibers within cables.

Early systems were often proprietary and varied between manufacturers. Over time, industry-wide standards were developed to ensure consistency and interoperability among different fiber-optic networks.

Standards Organizations and Their Roles

Several standards organizations play a critical role in developing and maintaining fiber color code standards. Some of the key organizations include:

- Telecommunications Industry Association (TIA): The TIA produces standards that cover various aspects of telecommunications, including fiber color coding. The TIA-598 standard is one of the most widely recognized guidelines for fiber-optic color coding.

- International Electrotechnical Commission (IEC): The IEC develops international standards for electrical, electronic, and related technologies. Their standards ensure global consistency in fiber color coding.

- American National Standards Institute (ANSI): ANSI oversees the development of standards for a wide range of industries in the United States, including fiber optics. They often collaborate with other standards bodies to ensure alignment and coherence.

These organizations work together to create and update standards that provide guidelines for color coding, ensuring that fiber-optic networks remain organized, efficient, and reliable across the globe.

The Basics of Fiber Optic Cables

Fiber optic cables are the backbone of modern telecommunication and data transfer systems. They work by transmitting light signals through hair-thin strands of glass or plastic fibers, offering significantly higher bandwidth compared to traditional copper cables.

Understanding the different types of fiber optic cables and their structures is essential for effective network design and implementation.

Types of Fiber Optic Cables

There are primarily two types of fiber optic cables used in the industry: Single-Mode Fiber (SMF) and Multi-Mode Fiber (MMF). Each type has its unique characteristics and applications.

Single-Mode Fiber

Single-Mode Fiber optic cables are designed to carry light directly down the fiber with minimal dispersion. They have a small core diameter, typically around 8 to 10 micrometers, which allows them to transmit data over long distances with lower loss. Single-Mode Fibers are ideal for long-haul telecommunication networks, cable television networks, and university campuses.

Multi-Mode Fiber

Multi-Mode Fiber optic cables have a larger core diameter, usually around 50 to 62.5 micrometers, which allows multiple modes of light to propagate through the core.

While this enables them to handle greater amounts of data and support shorter distances, it also increases the potential for modal dispersion. Multi-Mode Fibers are commonly used in shorter distance applications such as local area networks (LANs), data centers, and within buildings.

Structure of Fiber Optic Cables

A fiber optic cable is composed of three main parts: the core, the cladding, and the coating.

Core

The core is the central part of the fiber optic cable that carries the light signals. It is made from high-purity glass or plastic and has a refractive index higher than the surrounding cladding. The core’s diameter determines the type of fiber—single-mode or multi-mode.

Cladding

Surrounding the core is the cladding, which is also made from glass or plastic but with a lower refractive index. The cladding reflects light back into the core through the principle of total internal reflection, ensuring the light signals remain within the core as they travel down the fiber.

Coating

The outermost layer of the fiber optic cable is the coating, which provides physical protection and additional strength to the delicate glass or plastic core and cladding. The coating is typically composed of one or more layers of polymer material, which also helps to buffer external forces and enhance the durability of the cable.

Fiber Color Code Standards

The TIA/EIA 598 standard is a widely recognized and adopted specification in the telecommunications industry, providing a consistent method for identifying fibers in optical fiber cables.

Established by the Telecommunications Industry Association (TIA) and the Electronic Industries Alliance (EIA), it defines a color-coding scheme for both single-mode and multi-mode fibers. This coding system facilitates easy identification and management of fibers during installation and maintenance, reducing the risk of errors and increasing efficiency.

Color Codes for Fiber Types

The TIA/EIA 598 standard assigns specific colors to individual fibers within a fiber optic cable. Here are the primary color codes:

- Fiber 1: Blue

- Fiber 2: Orange

- Fiber 3: Green

- Fiber 4: Brown

- Fiber 5: Slate

- Fiber 6: White

- Fiber 7: Red

- Fiber 8: Black

- Fiber 9: Yellow

- Fiber 10: Violet

- Fiber 11: Rose

- Fiber 12: Aqua

These colors repeat every 12 fibers; for example, Fiber 13 would be blue again.

ISO/IEC Standards Overview

The ISO/IEC standards, developed by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), provide a global framework for fiber optic communication systems, including color-coding guidelines.

These standards ensure compatibility and interoperability of fiber optic systems worldwide, promoting uniform practices across different countries and regions.

Comparison with TIA/EIA 598

While the ISO/IEC standards provide a broad framework, the TIA/EIA 598 color code is more specific and detailed, particularly within the United States.

This targeted approach makes TIA/EIA 598 particularly useful for applications that demand strict adherence to a precise and universally recognizable color-coding scheme.

Other Regional and International Standards

European Standards

In Europe, the EN 50173 standard is commonly used, which aligns closely with the ISO/IEC standards but also incorporates regional specificities. This standard is crucial for ensuring consistency in the installation and management of fiber optic networks throughout Europe.

Asian Standards

Asian countries often adhere to national standards based on the ISO/IEC framework but may include variations to address local industry practices. For example, Japan uses the JIS (Japanese Industrial Standards) for optical fiber color coding.

The use of different standards across regions underscores the importance of understanding and applying the correct color codes to ensure seamless integration and operation of fiber optic systems globally.

Detailed Breakdown of Fiber Color Codes

Understanding fiber color codes is essential for anyone working with fiber optic cables. These color codes are established standards that help in the identification of individual fibers and ensure consistency across installations and maintenance activities. Here, we’ll delve into the color codes for various types of fiber cables.

Color Codes for Single-Fiber Cables

Single-fiber cables are typically used in straightforward connections where only one optical fiber is needed. The most common colors for these cables are yellow for single-mode fibers and orange or aqua for multimode fibers.

Color Codes for Multi-Fiber Cables

Multi-fiber cables, containing multiple optical fibers, follow more detailed color code standards to distinguish each fiber within the bundle.

12-Fiber Cables

For 12-fiber cables, the color sequence is as follows:

- Blue

- Orange

- Green

- Brown

- Slate (Gray)

- White

- Red

- Black

- Yellow

- Violet

- Rose (Pink)

- Aqua

24-Fiber Cables

In 24-fiber cables, the same 12-color sequence is repeated with additional markers to distinguish between the first and second sets of 12 fibers. Typically, the second set will have a black stripe or ring around the base color.

Ribbon Cables

Ribbon cables consist of fibers aligned in a flat, ribbon-like ribbon. These cables also follow the 12-fiber color code sequence, often repeated multiple times depending on the cable’s overall fiber count. Each ribbon in the cable is uniquely identified by its position and, sometimes, by additional markers.

Color Codes for Loose Tube Cables

Loose tube cables contain fibers loosely bundled within a larger protective tube. Color codes help in identifying fibers across multiple tubes:

- Individual fibers within each tube follow the 12-fiber color sequence.

- Tubes themselves may also be color-coded, typically using the same initial 12 colors.

Color Codes for Tight-Buffered Cables

Tight-buffered cables, which encase individual fibers in a protective buffer coating, follow the standard 12-fiber color codes:

- Blue

- Orange

- Green

- Brown

- Slate (Gray)

- White

- Red

- Black

- Yellow

- Violet

- Rose (Pink)

- Aqua

Correctly applying these color codes simplifies the process of identifying, managing, and troubleshooting fiber optic connections.

Summary

Key Takeaways

- Standardization: Fiber color codes adhere to established industry standards, such as ANSI/TIA-598, which specify the colors for each type of fiber in a multi-fiber cable.

- Identification: Each fiber within a cable is identified by its color, ensuring that technicians can quickly and accurately identify individual fibers during installation and maintenance.

- Efficiency: Proper knowledge of fiber color codes enhances operational efficiency, reducing the time needed for troubleshooting and minimizing the risk of errors.

- Training: Adequate training in fiber color codes is essential for all telecommunications and network professionals to maintain high standards of work quality and safety.

Fiber color codes are crucial in the telecommunication industry for identifying and organizing fiber optic cables. These codes follow standardized conventions to ensure uniformity across installations, facilitating efficient troubleshooting, maintenance, and upgrades. Understanding these color codes is essential for professionals working with fiber optics, as it prevents costly errors and downtime.

As technology evolves, the demand for higher bandwidth and faster data transmission continues to grow, leading to the development of new fiber optic technologies and applications.

The future of fiber color codes may see adaptations to accommodate these innovations, such as advanced multiplexing techniques and higher fiber counts. Staying abreast of changes in standards and continuously updating skills will be important for professionals to keep pace with the evolving landscape of fiber optics.

We help companies refine their messaging, hone in their sales process, and grow their pipeline – all with a new website.